LEED has released its latest version of standards, V4.1, which includes several updates to the LEED certification program. However, with this version, there is considerably more emphasis on water – and using water more efficiently and wisely.

But before we go into details, let’s ensure we are all on board as to what LEED is. LEED is part of the U.S. Green Building Council. Here is how the organization is defined on their website:

LEED (Leadership in Energy and Environmental Design) is the most widely used green building rating system in the world. Available for virtually all building types, LEED provides a framework for healthy, efficient, and cost-saving green buildings. LEED certification is a globally recognized symbol of sustainability achievement and leadership.

In its early days, LEED put considerable emphasis on energy and fuel conservation and the use of green-certified cleaning solutions. Over the years, its scope has increased considerably, expanding to how facilities are built, the materials used to make those facilities, how they are operated and maintained, and now, water and water management systems in these facilities.

We should also know that since its founding in 1993, LEED has had a significant impact on facilities and the owners and managers of these facilities. Today, over 93,000 facilities are LEED-certified or registered for LEED certification.

For a facility to earn this certification, it must receive so many points or credits. At one time, reducing water consumption in a facility by 11 percent would earn a specific number of LEED credits. But now the tables have been turned. To even be considered for LEED certification, a facility must show that it has reduced water consumption by 11 percent or more. In other words, it is now a prerequisite.

Further, because nearly 20 percent of LEED’s certification points now relate to water, before awarding LEED points, version 4.1 compares the water performance of one building to comparable high-performing buildings.

Tracking Water Consumption

Being LEED certified has always involved providing the organization with considerable amounts of data. But this data serves an essential purpose, especially regarding water. The data is the only way to track water reduction progress. Further, it helps building owners and managers know what and where improvements are needed when it comes to water reduction to meet LEED standards.

So, what steps can facilities take to earn these points and how many can they earn? Below are the corresponding point values:

• By installing a rainwater management system, a facility can earn up to three points.

• No or low-cost potable water preservation one point.

• More water-efficient cooling systems, three points.

• Innovation in new construction related to water reduction, 1 point.

• Overall exemplary performance, 2 points.

• Reduce indoor water use by 6 points.

A Closer Look at Indoor Water Use

It is evident that most LEED points associated with water revolve around minimizing indoor water consumption. Therefore, how can commercial facilities like offices, schools, airports, or similar establishments reduce water consumption over the long term? Here are a few approaches they can adopt:

Install automated software systems that track water usage in the facility. In larger buildings, it's best to install multiple systems that monitor water consumption in different areas to alert managers of any issues in those areas and even regulate water usage in some parts of the building.

Place a greater focus on water usage in restrooms, where most water is used. Installing water-efficient faucets that use aerators can dramatically reduce consumption while still meeting user satisfaction.

Toilets are another significant contributor to water consumption. Even if they were initially designed to use 1.6 gallons of water per flush, age, and wear can cause them to use more water. In most cases, toilets should be replaced after about seven years to prevent excessive water usage.

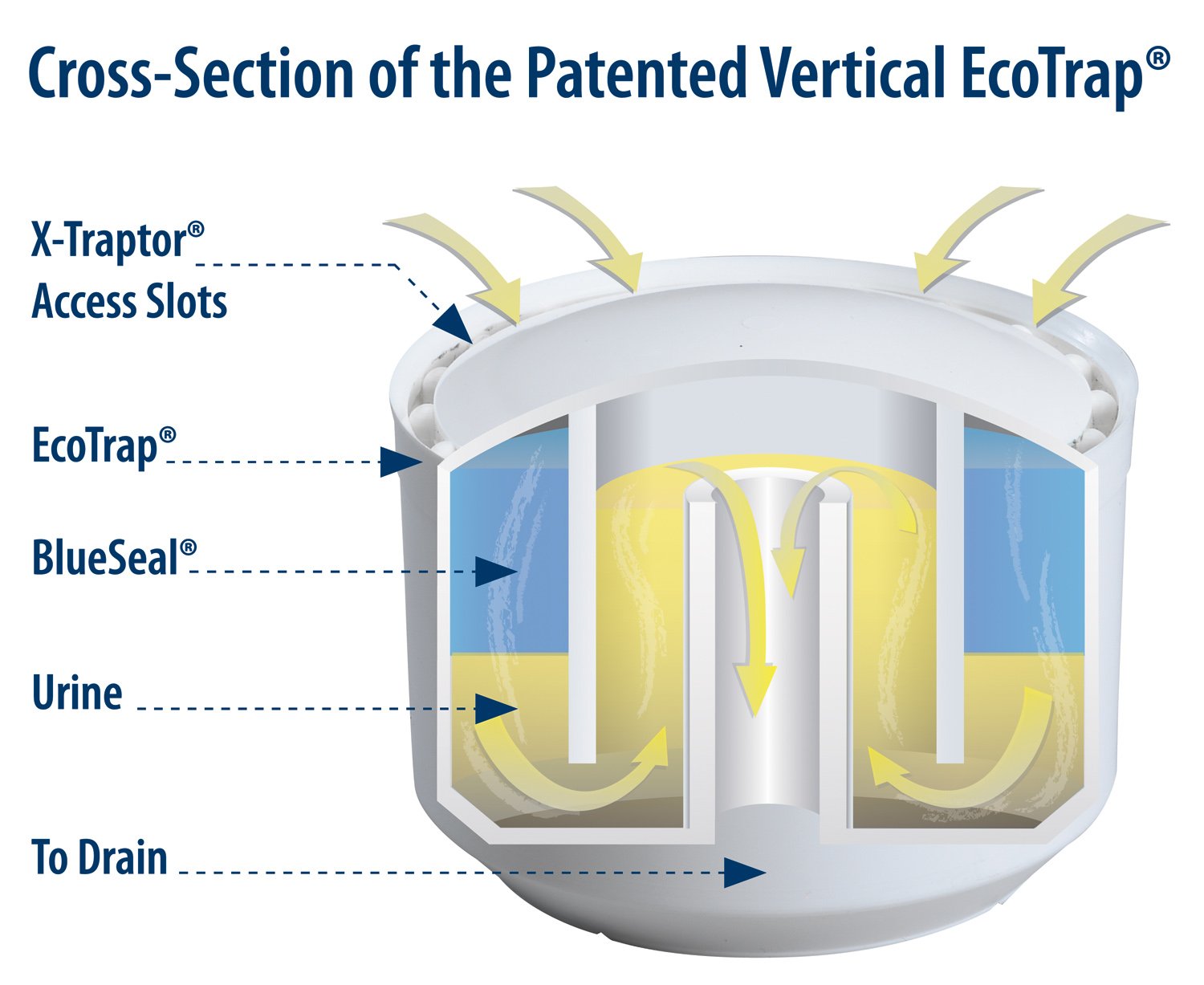

Waterless urinals should be installed. Installing waterless urinals can often help facilities meet LEED requirements for water reduction without making any other modifications.

Benefits of LEED Certification

Let's address one more issue. Why is LEED certification necessary? Are facilities just making their facilities more efficient, greener, and sustainable because it's the "right thing to do?" Hardly.

Today, commercial buildings are finding it very difficult to get tenants. If a facility is LEED certified, that is a big feather in this facility's cap, helping secure tenants.

Reducing water consumption promotes sustainability. According to the World Economic Forum, 60 percent of organizations globally have developed sustainability standards because they believe sustainability will be crucial to their market differentiation and financial performance in the coming years.

Finally, reducing water consumption saves money. Remember, we pay for water twice: once it's delivered and once again when it is taken away. The less water used and then returned to treatment facilities can be a considerable savings for large facilities.

Klaus Reichardt is CEO and founder of Waterless Co, Inc, pioneers in advancing water efficiency. Reichardt founded the company in 1991 with the goal of establishing a new market segment in the plumbing fixture industry with water efficiency in mind. Reichardt is a frequent writer and presenter, discussing water conservation issues. He can be reached at klaus@waterless.com